Why Bridger

Technology and Methodology That Set Bridger Apart

Unmatched sensitivity, precise localization, and a process built for accuracy and trust.

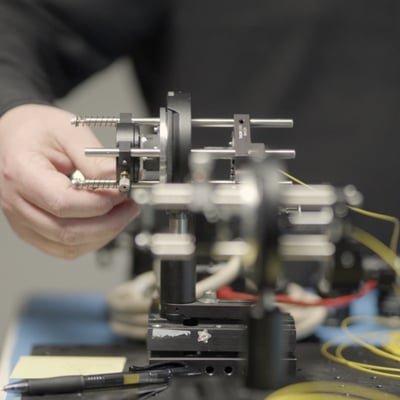

The Technology Behind Bridger

The cornerstone of what we do is actionable data, powered by our state-of-the-art laser technology, Gas Mapping LiDAR.

Designed to make emissions reduction simple, our technology was built to detect, quantify, and pinpoint methane emissions with unrivaled accuracy, empowering organizations to tackle leak detection, repair, and strategic emissions management more efficiently than ever before.

Our unique approach leverages state-of-the-art LiDAR technology to gather detailed emissions data—without the need for site access or installing emissions measurement equipment. The result? Clear, accurate data and analytics that shows exactly what’s leaking, where it’s leaking, and how much is being lost.

Why Our Data Stands Out

At Bridger, our industry-leading aerial LiDAR technology detects, quantifies, and pinpoints methane emissions, providing accurate data tailored for effective leak detection and repair, and for strategic emissions management. Key differentiators include:

Unbeatable Actionability

With pinpoint localization and clear imagery, your crews know where to go with Bridger's data.

Industry-leading Sensitivity

Flexible methane detection down to 1 kg/hr with ≥90% probability of detection (PoD) for the production and transmission sectors, and down to 0.5 kg/hr with ≥90% PoD for utilities.

Unmatched Reliability

We have scalable coverage that scans in varied weather and terrain, unlike many competing technologies.

Scale + Sensitivity together

Covers hundreds of production facilities, miles of gas pipeline per day, or full LNG facilities without sacrificing accuracy.

Rigorous Validation

Be confident that the data you receive is both defensible and trusted by industry leaders.

-1-1.png?width=400&name=Bridger%20Treatment%20for%20Images%20Template%20(1)-1-1.png)

Where others force a trade-off between sensitivity and coverage, Bridger delivers both.

Simplifying Success: Learn What It's Like to Work with Bridger

Kick-off Meeting

You’ll meet your Bridger team to review goals and align expectation.

Scan and Data Capture

We manage all logistics for the aerial scans, efficiently capturing highly accurate methane data.

Data Analyzed by Experts

Our team of expert data analysts review your data, utilizing state of the art AI and ML tools to ensure your data's quality.

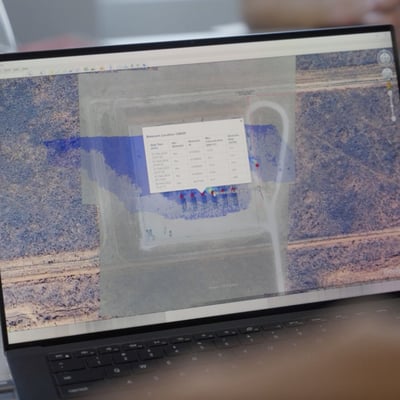

Receiving Your Data

We provide your data via several options, including easy to access API channels, helping you act faster.

Data Debrief

Our expert team will review your data with you, ensuring you're getting the most out of your partnership with Bridger.

The results are clear, actionable emissions data that leads to confidence in the field: crews can walk directly to the leaking piece of equipment, EHS teams can track inventories with certainty, and executives can report defensible progress to regulators, investors, and boards.

Future-Ready Capabilities

Methane detection is evolving quickly. Bridger’s technology and methodology are at the forefront. We have:

Adaptable platforms

Deployed from small aircraft, helicopters, or drones depending on environment and need.

Sensitivity that scales

We scale with operators, advancing detection thresholds as needed over time to find even smaller leaks.

Framework alignment

Continuous engagement with regulators, operators, and voluntary frameworks ensures compatibility with current and future requirements.

Why Operators Rely on Bridger

Accuracy and usability are built into every step of our process.

That’s why leading operators across production, transmission, LNG, distribution, and landfills use GML to measure, manage, and mitigate methane.

Talk to an Expert

Let’s find out how GML can support your methane management goals.