GML for LNG

The gold standard in methane detection for complex LNG facilities

Trusted By Industry Leaders

Operators working with liquefied natural gas (LNG) face unique challenges when it comes to methane detection.

LNG plants are sprawling, high-risk environments with flare stacks, piping, compressors, and storage tanks packed into dense footprints. Ground crews can’t easily reach every corner, traditional monitoring struggles with scale, and investors are demanding reliable, transparent emissions reporting.

Bridger’s GML for LNG is designed for exactly this environment. Already trusted by global leaders like Cheniere and Chevron, GML delivers unmatched sensitivity, facility-wide coverage, and audit-ready reports that meet the highest regulatory and voluntary standards.

Why LNG Companies Choose Bridger

Gold-standard accuracy

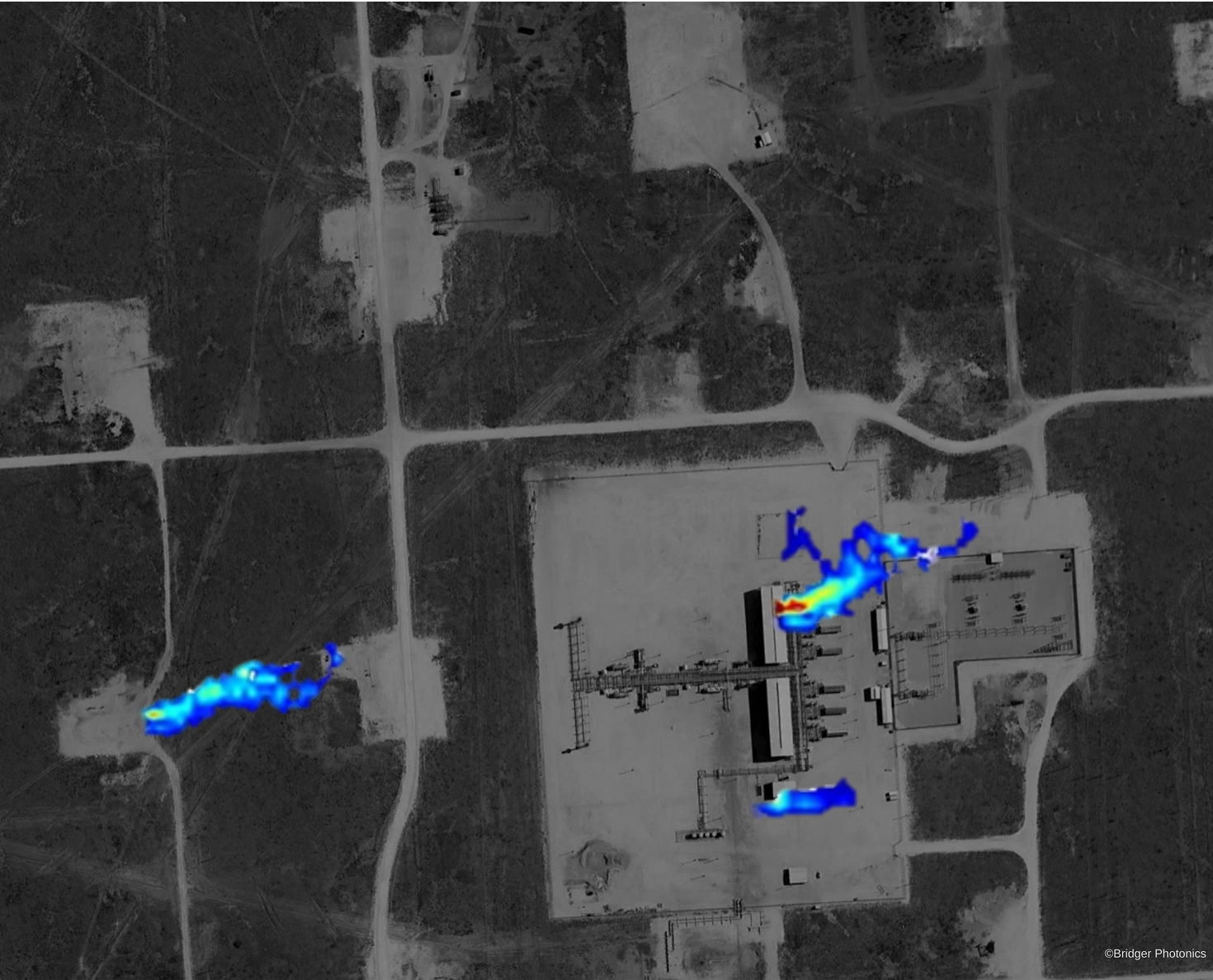

With detection sensitivity down to 1 kg/hr with a 90% probability of detection, and source attribution within approximately 2 meters (~6 feet), GML sets the benchmark for methane detection for LNG. That level of precision means leaks are pinpointed, quantified, and defensible, whether for regulators, investors, or certification programs.

Facility-wide coverage without disruption

Entire LNG export terminals can be scanned in days, not months, with no boots on the ground and no added safety risks. Our sensors cover every inch of infrastructure, from flare stacks to piping.

Audit-ready, investor-grade data

Reports are aligned with OGMP 2.0 Level 5 and other voluntary emissions reporting frameworks, providing traceable, time-stamped, georeferenced emissions data that easily stands up to regulatory review and investor scrutiny.

Trusted and proven in LNG

Adopted by the industry’s largest operators, including Cheniere and Chevron, GML has become the gold standard for methane detection in export facilities—trusted for its precision, efficiency, and scalability.

Designed for LNG’s Unique Challenges

Dense, Complex Infrastructure

Scanning is conducted across all LNG infrastructure including flare stacks, compressors, and cryogenic tanks—without blind spots and using the best-in-class detection sensitivity

Safety-critical environments

Aerial LiDAR monitoring eliminates the need for ground crews in hazardous zones

Global expectations

Supports LNG operators facing heightened investor, regulatory, and international scrutiny

Compliance and Beyond

Methane regulations and voluntary frameworks increasingly demand precision, auditability, and proof of emissions reductions. GML is:

- EPA-approved for OOOOb/OOOOc compliance at every sensitivity tier

- Aligned with OGMP 2.0 Levels 4 and 5, ensuring credibility for investor and certification reporting

- Scalable globally, with proven results across U.S. and international LNG facilities

Talk to an LNG Expert

The world’s leading LNG operators already trust Bridger. Find out how GML can support your methane management, compliance, and reporting goals.