A Summary of Bridger’s Comments on PHMSA’s Proposed Rule

In May of 2023, the Pipeline and Hazardous Materials Safety Administration (PHMSA) released a proposed rulemaking titled “Pipeline Safety: Gas Pipeline Leak Detection and Repair”. This proposed rulemaking expands the scope of required gas pipeline surveys and prescribes performance standards for leak detection equipment.*

Bridger Photonics submitted comments requesting revisions to the proposed rule that would give operators uncompromised access to aerial remote sensing technology for pipeline leak detection. Although previous PHMSA rules did not specify what type of technology was required for pipeline leak detection, operators identified and implemented the best available options. This included the widespread adoption of laser-based remote sensing technology due to its efficiency and efficacy. However, in the latest proposed rule, using remote sensing-based technologies would require a separate approval process because the default performance requirements are incompatible with the way that remote sensing measures gas. To streamline implementation of remote sensing tech for PHMSA regulatory compliance, Bridger requests the following three key revisions:

- Incorporate leak detection performance requirements defined by an emission rate detection sensitivity (instead of gas concentration units).

- Include a leak detection requirement of 4 kg/hr with a 90% probability of detection (PoD) for gathering and transmission pipelines.

- Align with the U.S. Environmental Protection Agency (EPA) on approved test methods for methane leak detection.

The following is a summary of Bridger’s comments. Access to the full version can be found here or at the bottom of this page.

Use Emission Rate Detection Sensitivity to Define Leak Detection Approach Performance

In the proposed rule, leak detection sensitivity performance standards are defined in parts-per-million (ppm), which is incompatible with remote sensing measurements. Conversely, remote sensing detection sensitivity is commonly assessed according to the emission rate (mass flow rate) that is reliably detected. To make it easy for operators to use remote sensing for regulatory compliance, we recommend that PHMSA includes additional default performance standards defined by mass emission rate detection sensitivity (e.g., kg/hr) with an associated PoD. Additional benefits to assessing leak detection performance in terms of emission rate detection sensitivity include:

- Emission rate is a fundamental property of leaks.

- Emissions reduction goals are often evaluated using emission rates.

- This approach is consistent with the EPAs’ proposed framework for implementing advanced methane sensing technology.

Require a Detection Sensitivity of 4 kg/hr with 90% PoD

A minimum leak detection requirement of 4 kg/hr with a 90% PoD will provide practical and effective emissions reduction.

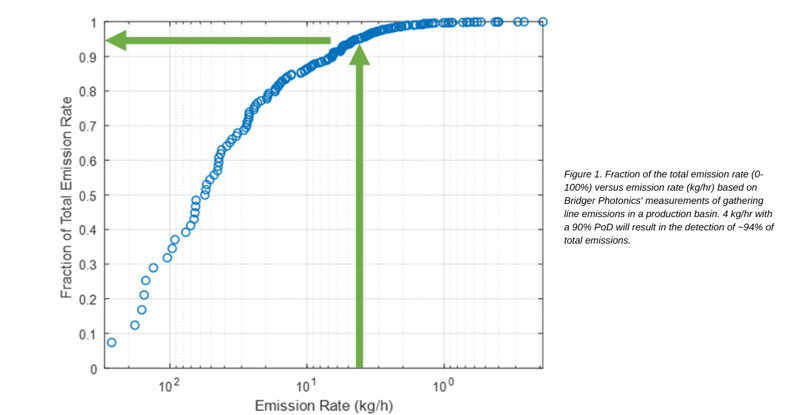

To determine an effective sensitivity threshold for midstream pipelines, Bridger gathered data from thousands of miles of pipelines that we’ve scanned to create emission rate distributions. For the distribution shown in Figure 1, Bridger found that leaks with emission rates above 4 kg/hr account for more than 94% of the aggregate measured emission rate (as indicated by the arrows on the figure).

Based on this result, a 4 kg/hr emission rate detection sensitivity requirement would create a practical threshold that enables effective emissions reduction as long as it is tied to the requirement to detect emissions of that size with a high probability (e.g. 90% of the time).

Align with EPA on Alternative Test Methods and Performance Metrics

Finally, we urge PHMSA to accept suitable EPA-approved alternative test methods for leak detection at natural gas pipelines.

By utilizing EPA-approved alternative test methods that provide suitable detection sensitivity for pipeline detection, PHMSA will provide operators with compliance tools in a timely manner and without the burden of extensive additional performance demonstration. There are also considerable safety, environmental, and economic benefits to allowing operators to use the same leak detection methods for pipeline scans as for EPA-regulated assets that the pipelines are connected to. PHMSA-regulated pipelines are connected to EPA-regulated surface assets, so if agency standards are aligned, the leak detection process is streamlined and simplified.

Alignment on approved technologies between the EPA and PHMSA would allow operators better access to advanced technologies and make it more efficient to evaluate collocated pipelines, compressor stations, and upstream infrastructure.

For more detail, read Bridger's full comment letter here:

Want to discuss using Gas Mapping LiDAR for pipelines? Start the conversation by emailing us at info[at]bridgerphotonics.com or by filling out this form.

*In addition to pipeline leak detection and visual right-of-way (ROW) inspections, the rulemaking included additional measures to reduce emissions and increase safety. Reporting requirements were also increased and rules for other facilities like liquified natural gas (LNG) facilities and gas storage fields were also amended.